When a manufacturing line starts producing defective parts, the immediate instinct is to stop the line, throw away the bad units, and fix the machine. But that’s just a correction-not a solution. Without digging deeper, the same problem comes back next week, then next month, and soon you’re drowning in scrap, customer complaints, and regulatory warnings. Real quality improvement doesn’t come from patching symptoms. It comes from corrective actions-structured, documented, and verified steps that kill the root cause so the problem never returns.

What’s the Difference Between Correction and Corrective Action?

A correction is a quick fix. You see a misaligned label on a medicine bottle? You reposition the printer. You notice a batch of pills with the wrong color coating? You scrap the batch and recalibrate the mixer. Done. But the label still misaligns. The coating still flakes. Why? Because you didn’t ask why it happened. Corrective action is different. It’s a process. It starts when someone asks: Why did this happen? And then: How do we make sure it never happens again? This isn’t about fixing the last bad unit-it’s about fixing the system that let it happen. In regulated industries like medical devices and pharmaceuticals, this isn’t optional. FDA 21 CFR Part 820 and ISO 13485 require manufacturers to prove they’re not just fixing problems-they’re eliminating them. The FDA issued over 1,200 warning letters in 2022, and 43% of them cited poor corrective action. That’s not a typo. Nearly half of the quality failures in top companies weren’t because of bad machines or sloppy workers. They were because the company didn’t do the work to find the real cause.The Six-Step Corrective Action Process

Every effective corrective action follows the same six steps. Skip one, and you’re gambling with compliance, cost, and reputation.- Identify the problem - It starts with data. A quality inspector catches a dimension out of spec. A customer returns 12 units with cracked housings. A sensor triggers an alarm on the assembly line. These aren’t just incidents-they’re signals. The best manufacturers track every deviation, no matter how small. Even a 0.1% defect rate matters when you’re making a million units a year.

- Evaluate and categorize - Not all problems are equal. A misprinted expiration date on a drug bottle is a critical issue. A slightly off-color cap on a shampoo bottle? Less so. Manufacturers use risk-based scoring to prioritize. High-risk problems trigger full corrective action. Low-risk ones might get a simple correction. The key is consistency. If you treat every issue the same, you waste time. If you ignore small ones, you miss patterns.

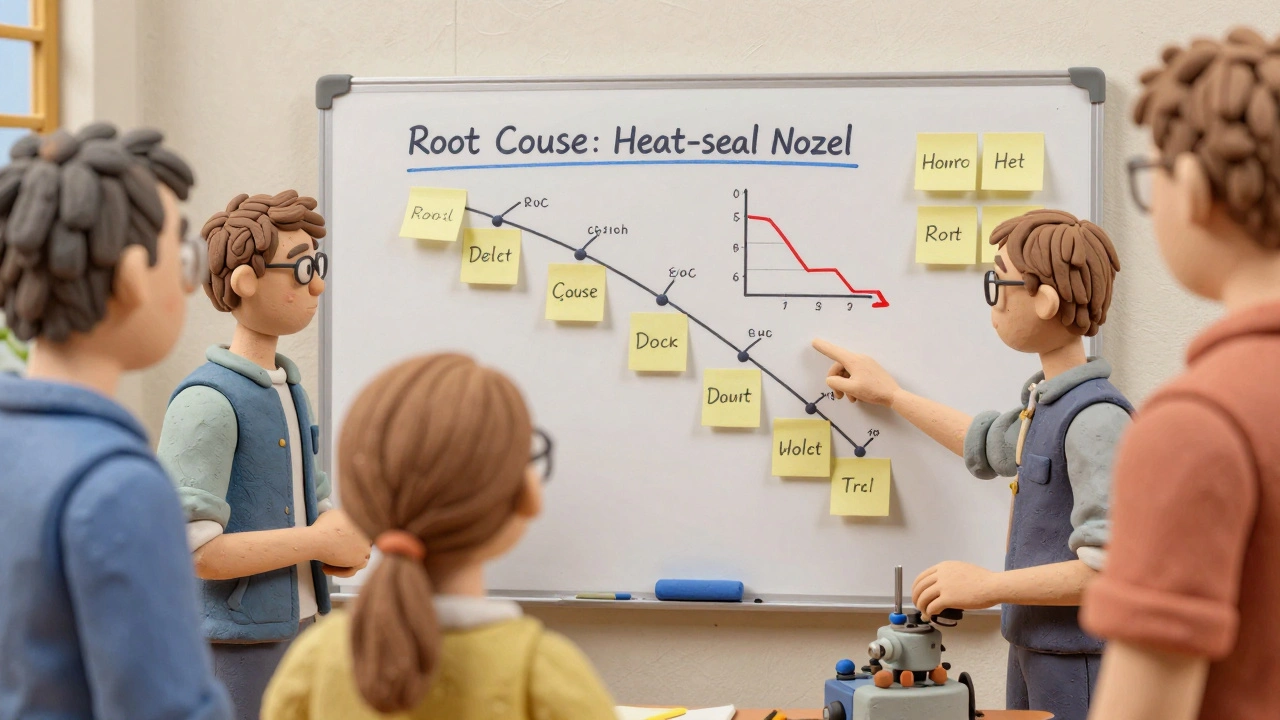

- Find the root cause - This is where most fail. Too many teams jump to the first obvious cause: “The operator didn’t follow the procedure.” But why didn’t they? Was the training outdated? Was the work instruction unclear? Was the tool hard to use? The 5 Whys method helps here. Keep asking “why” until you hit something systemic. A fishbone diagram (also called an Ishikawa) maps out possible causes across categories: people, process, equipment, materials, environment, and measurement. One medical device maker found their implant packaging leaks weren’t due to operator error-they were caused by a new supplier’s material that reacted differently to their heat-sealing machine. That’s a root cause. Not the operator.

- Plan the fix - Once you know the cause, you design a solution. This isn’t a guess. It’s a plan with: specific actions (e.g., “Replace heat-seal nozzle model X with model Y”), clear deadlines (“Complete by March 15”), assigned owners (“John Rivera, Maintenance Lead”), and verification steps (“Test 50 sealed units under 40°C for 72 hours”). The plan must be measurable. “Improve quality” is not a plan. “Reduce seal failure rate from 1.2% to under 0.1% in 30 days” is.

- Implement the fix - Now you execute. Train staff. Update SOPs. Install new parts. Change software settings. This step fails when people don’t follow the plan. That’s why documentation matters. Every change must be recorded. Not just “we fixed it.” But “we replaced nozzle on Line 3 at 10:30 AM on March 10. Verification test results attached.” Auditors don’t care about your good intentions. They care about your paper trail.

- Verify effectiveness - Did the fix work? You can’t assume. You have to prove it. This means running tests after implementation. For process changes, you need at least 30 samples to be statistically valid. For equipment changes, you need calibration records. For training changes, you need competency assessments. One automotive supplier reduced bearing defects by 89% after replacing a worn fixture. But they didn’t stop there. They ran 60 days of production data and showed the defect rate stayed below 0.05%. That’s verification. That’s proof.

Why Most Corrective Actions Fail

You’d think this process is straightforward. But in practice, 57% of failed corrective actions, according to FDA data, never truly identified the root cause. Why? - Too much paperwork, too little thinking - Some companies treat CAPA like a compliance checklist. They fill out forms, attach photos, and file them away. But if no one actually investigates, it’s just theater. One quality manager on Reddit said their system generated 47 pages per issue. “We spent more time writing than fixing.” - No accountability - If no one owns the fix, it dies. A CAPA with five “responsible parties” is a CAPA with no one responsible. The best systems assign one person-no more, no less-to drive each action to completion. - Verification is skipped - “We changed the machine setting. It’s fine now.” That’s not verification. Verification means testing. Measuring. Tracking over time. Without it, you’re just hoping. - Ignoring trends - A single defect is a problem. Three defects in the same part over two weeks? That’s a system failure. ISO 13485:2016 now requires manufacturers to trend data. If you’re seeing the same error pop up in different lines or batches, it’s not coincidence. It’s a design flaw, a training gap, or a supplier issue. Corrective action must catch these patterns before they become recalls.

Technology Is Changing How CAPA Works

The old way: paper forms, Excel spreadsheets, email chains. The new way: integrated digital systems that connect quality data to production in real time. Manufacturers using AI-powered tools are cutting root cause analysis time by over half. One company used machine learning to analyze vibration patterns from 200 assembly machines. The system flagged a subtle change in motor torque on Line 7-three days before any part failed. That’s predictive CAPA. It’s not waiting for a problem. It’s preventing it. Electronic CAPA systems reduce documentation time by 41%, according to Tulip’s 2023 data. They auto-generate audit trails, link actions to equipment logs, and trigger alerts when deadlines are missed. The FDA’s 2023 Digital Health Plan encourages this. Over 40% of medical device makers are now piloting blockchain-backed CAPA systems-tamper-proof, time-stamped, and instantly verifiable. The future? Systems that don’t just react to problems-but predict them. Gartner predicts 65% of manufacturers will use predictive CAPA by 2027. That means fewer recalls, less downtime, and lower costs.What Works in Real Factories

Look at real results: - An automotive parts maker reduced defects from 2.8% to 0.4% in 18 months by using cross-functional teams. Quality, engineering, and production met weekly to review every CAPA. No silos. No blame. - A pharmaceutical company cut regulatory findings by 34% after assigning a single CAPA owner per department and linking all actions to their ERP system. Audits became easier because everything was traceable. - A small medical device firm with 30 employees didn’t need fancy software. They used a simple Google Sheet with clear columns: Problem, Root Cause, Action, Owner, Deadline, Verification Result. They reviewed it every Monday. Within a year, their customer complaints dropped by 70%. The common thread? Discipline. Not technology. Not budget. Discipline in asking why, documenting what, and proving it worked.

When Is a Full CAPA Overkill?

Not every manufacturer needs a full FDA-style CAPA system. If you’re making 50 custom parts a week with low regulatory risk, a heavy CAPA process might cost more than the defects it fixes. In low-volume, low-risk environments, a simplified “corrective action” approach works: document the issue, fix it, note why it happened, and check in a week to make sure it’s stayed fixed. No 47-page forms. No statistical validation. Just common sense. But if you’re regulated-if your product touches a human body, runs on a plane, or powers a hospital machine-then you don’t get to skip the hard work. The cost of skipping it? Fines. Recalls. Lost trust. Sometimes, lives.Final Takeaway

Corrective action isn’t about being perfect. It’s about being honest. It’s about admitting that systems fail-and then having the discipline to fix them, not just cover them up. The best manufacturers don’t fear defects. They use them. Every defect is a lesson. Every CAPA is a chance to make the next batch better. If you’re still treating quality problems like fire drills-put out the flame, then forget it-you’re not fixing anything. You’re just delaying the next one.What’s the difference between corrective action and preventive action?

Corrective action fixes a problem that already happened. Preventive action stops a problem before it happens. For example, if a machine keeps overheating and causes defects, corrective action replaces the faulty thermostat. Preventive action installs a temperature monitor that alerts operators before overheating occurs. Preventive actions are proactive. Corrective actions are reactive-but both are needed for strong quality systems.

How long should a corrective action take to complete?

There’s no universal timeline. Simple issues might be resolved in a week. Complex root causes-like supplier material changes or design flaws-can take 3 to 6 months. The key is not speed, but thoroughness. The FDA and ISO require verification, which often needs multiple production cycles to confirm effectiveness. Rushing leads to recurrence. Patience pays.

Do all quality issues require a full CAPA?

No. Only issues that impact product safety, performance, or regulatory compliance need full CAPA. Minor, one-time errors-like a misprinted date on a non-critical label-can be handled with a simple correction and log entry. Regulators expect proportionality. Using CAPA for every small issue creates unnecessary work and distracts from real risks.

What happens if you don’t complete a corrective action?

In regulated industries, incomplete CAPAs lead to regulatory citations. The FDA cited CAPA failures in 28% of medical device inspections in 2023. This can trigger warning letters, product holds, or even manufacturing shutdowns. Outside of regulation, incomplete actions mean recurring defects, higher scrap rates, and eroded customer trust. The cost of inaction is always higher than the cost of doing it right.

Can software replace human judgment in corrective actions?

No. Software can track, remind, and analyze data-but it can’t ask why. Root cause analysis still needs experienced people who understand the process, the equipment, and the human factors. AI can suggest possible causes, but a human must validate them. The best systems combine data-driven tools with skilled teams. Technology supports, but doesn’t replace, good judgment.

Jessica Baydowicz

December 2, 2025 AT 01:13Martyn Stuart

December 2, 2025 AT 01:42Shofner Lehto

December 2, 2025 AT 16:14Libby Rees

December 3, 2025 AT 22:24Dematteo Lasonya

December 5, 2025 AT 16:35Rudy Van den Boogaert

December 7, 2025 AT 11:30Gillian Watson

December 8, 2025 AT 08:55Jordan Wall

December 10, 2025 AT 04:08Gareth Storer

December 10, 2025 AT 09:14Pavan Kankala

December 10, 2025 AT 10:07val kendra

December 11, 2025 AT 15:34Elizabeth Crutchfield

December 11, 2025 AT 18:23Ben Choy

December 11, 2025 AT 21:37Emmanuel Peter

December 12, 2025 AT 06:11Ashley Elliott

December 13, 2025 AT 16:28Chad Handy

December 14, 2025 AT 23:17Augusta Barlow

December 15, 2025 AT 00:17Chase Brittingham

December 15, 2025 AT 15:01Bill Wolfe

December 16, 2025 AT 22:50